Its combination of energy efficiency, structural solidity,

resource conservation and low construction costs heralds a radical

change in the way homes and communities around the world can be

designed and built. With the ability to accommodate the ultimate in

creative expression due to it’s design flexibility. The construction

method does include such perks as tax breaks, generation of greenhouse

gas credits, reduced in insurance premiums and lower maintenance costs

an unlike other construction does not depreciate. The ultimate in

extreme weather housing, the insulation provided by the composite

materials is effective enough that the house can be heated or cooled

using less than half the energy it takes for a home built with

conventional materials. The foam / concrete house is more resistant to

fire, mold and pests than typical homes, and better able to withstand

such hazards as earthquakes, extreme weather, climate conditions and

flooding with it’s resistance to water. It natural resistance to pests

both insects and rodents reduce the costs associated with pest control,

exposure to toxic pesticides and the diseases transmitted by them. The

available non-porous interior designed without cracks and crevices

makes sterilization and cleaning a breeze. Complimented by the use of a

natural non-toxic residue free biocide, Anolyte solution, the same used

by the human body to destroy pathogens, created using salt water and

sunlight reduces the risk of contagions producing disease. The ultimate in

extreme weather housing, the insulation provided by the composite

materials is effective enough that the house can be heated or cooled

using less than half the energy it takes for a home built with

conventional materials. The foam / concrete house is more resistant to

fire, mold and pests than typical homes, and better able to withstand

such hazards as earthquakes, extreme weather, climate conditions and

flooding with it’s resistance to water. It natural resistance to pests

both insects and rodents reduce the costs associated with pest control,

exposure to toxic pesticides and the diseases transmitted by them. The

available non-porous interior designed without cracks and crevices

makes sterilization and cleaning a breeze. Complimented by the use of a

natural non-toxic residue free biocide, Anolyte solution, the same used

by the human body to destroy pathogens, created using salt water and

sunlight reduces the risk of contagions producing disease.

Compared to other environmentally sensitive, energy-efficient

construction methods this technique used for the foam house is better

by every measure. The method may have its greatest potential for a

significant impact in Third World nations. Foam / Concrete composite

buildings could be the answer to housing growing populations more

affordably, as well as more securely, particularly in regions

threatened by extreme climate chaos or prone to earthquakes. Optimized

for countries that do not have wood, steel, and other materials for

infrastructure, or which can be very expensive in those that do have

the resources. It can take months or up to three years to build just

one house, with this approach a house can go up in a matter of days.

Test results also scored well in the Scottsdale Green Building program.

The components rated very high 80-points, indicating sustainability. In

terms of energy conservation, materials reduction, and other

environmental elements, it proved exceptionally earth friendly. The

buildings conserve raw materials by eliminating the need for

conventional structural components such as wood or metal framing,

straps, nails, wallboard, stucco, and insulation. The structures are

energy-efficient, with an energy rating of R40 in the walls and R100

for roofs. Typically found in homes, fiberglass blankets of insulation

have a nominal R-value rating of less than half of polystyrene foam.

Higher R-values translate into less energy consumption for heating and

cooling. It replaces every structural component, including walls,

floors, and roof, providing a near air-tight-building envelope.

The new construction method and material is being targeted for use in

45 acre spiritual retreat, conference / workshop center, pod housing

and sustainable living prototype in New Mexico. One using surface soil remineralization in

place of petroleum based fertilizers and pesticides and Amaranth as a food

staple.

The new composite building system features a patented building

technique and material composed of expanded polystyrene foam coated

with a structurally reinforced concrete composite. These materials form

an incredibly strong bond to withstand building loads. Fibers are

disbursed throughout the matrix of the composite, which makes the

material three to five times stronger than steel. The foam cores are

over 98% air and provide the means to hold an outer concrete skin that

gives the structure its strength. When completed the structure is a

single seamless structure multiple components becoming one very solid

structure without cracks or crevices or structure weakening joints.

These bonded components are inexpensive to maintain, durable, and

resistant to fire, mold, pests, earthquakes and extreme weather and

wind conditions. The structure also provides superior insulating

qualities reducing the energy requirements for heating and cooling

combined with special ventilation the house is passive and sustainable

energy sources like wind, solar, and geothermal can easily meet all

energy requirements.

The structures can also be supplemented with additional technology to

provide shielding from electromagnetic radiation. The structure itself

can be turned into a large solar cell allowing for a distributed

decentralized energy infrastructure with each unit able to feed the

grid with surplus energy when equipped with battery storage. Each unit

is intelligently connected to a wireless mesh communications network

supported by each individual unit connected to all the rest as one

contiguous whole, for voice, data, and video. This allows hospitals and

manufacturing facilities to negotiate energy draws from each individual

unit providing fail safe distributed energy architecture.

The technique binds the lightweight foam and a glass fiber-reinforced

concrete. Crucial to this method becoming viable is a special computer

program that takes an architectural design and slices it up into pieces

allowing the data to be fed to computer controlled foam cutters, which

produce the pieces for easy assembly. The light weight foam pieces

allow large panels to be lifted into place by a single worker.

The architects CAD/CAM design is processed generating digital

instructions that directed a robotic foam cutter to accurately carve

the polystyrene shapes required for the building. The end result is a

set of building blocks that may be curved, angular, or the more

traditional square and rectangular shapes. These individually fashioned

pieces are assembled onsite like LEGOs. The rectangular panels range up

to four by eight feet. Exterior walls are eight to ten inches thick,

and interior walls are four inches thick. Patented roof beams,

manufactured out of polystyrene foam and concrete composite, are

thirty-inch thick supports.

The box frame design is much stronger than conventional

construction. This increases the maximum span without requiring

internal supporting walls or posts. “Clear Span” construction provides

the designer free reign to use up to 40 feet of unobstructed space

between walls. After assembly with a special adhesive, the foam is

spray coated with cement creating a single one piece unit.

Special tools, such as nail guns, electric saws, or compressors, are

not necessary in the construction of a home. In actuality, the most

unusual machine needed during construction is a hotwire tool that is

used to cut out windows, doors, or other openings from the foam blocks.

Any mistakes are easily fixed with a handheld foam gun. It’s a

forgiving system that can be repaired easily with unskilled labor. A

worker can be taught to do the job in two or three days. And it is a

lot easier than wood frame construction.

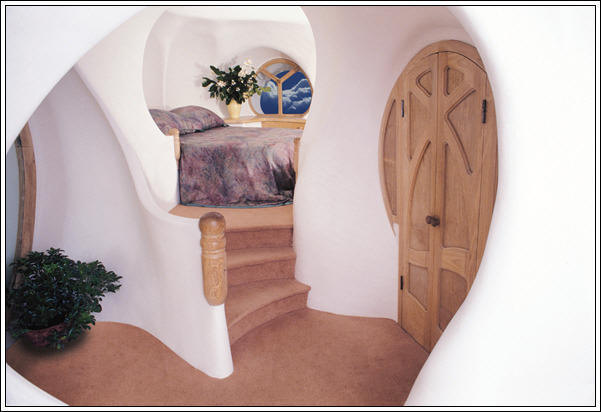

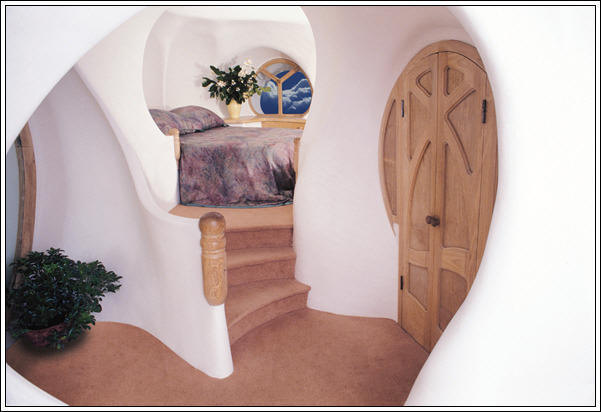

The fusion of the foam and a glass fiber-reinforced concrete materials

offers enough strength and durability to construct a house without

using any standard framing or reinforcement — wood, steel or otherwise

— and without a single nail, bolt or screw. The result is a seamless

single piece structure limited in form only by the imagination the

design whether it be a conventional ranch, English Tudor, adobe or any

style that could be imagined including a house without right angles

having only curved surfaces.

The other important achievement making this technology viable

is a patented method of predicting the performance of the structural

members of an entire building composed of these composites. Traditional

composite materials have had limited application in the building

industry because there have been no practical means for predicting the

performance of buildings using composites as structural members.

Desktop computing in the last few years advanced to the point where a

program could simulate the effects of earth movement, wind, snow load,

and other natural forces on these composite structures. The drawings of

the proposed building are used in concert with a mathematical program

called Finite Element Analysis. FEA is used to predict the performance

of the structure against the forces of nature. A performance record of

the building is available for review by architects, builders, and local

building authorities.

One major milestone and proof of viability was the passing of a series

of durability tests that conform to International Commercial Code (ICC)

standards. ICC requires a myriad of tests performed by an independent

laboratory for fire, aging, x-rays, water absorption, freeze/thaw, salt

spray, water penetration, seismic, and structural strength. it is clear

from the computer modeling that all aspects of structural concerns can

be met with this technology – wind, earthquakes, ground settling, etc.

which may become much more important in the near future with the threat

of Global Climate Chaos and extreme weather.

If the construction method is applied on a large scale, an

economy of scale is created resulting in costs well below those built

with conventional materials. Build time is very short, a few days,

which means a large number of units can be built and habitable within

weeks making it appropriate for rebuilding large areas ravaged by

extreme weather, earthquakes or other destructive forces.

The walls consist of 8-inch-thick blocks of polystyrene coated with a

quarter inch thick "skin’ of the fiber concrete. The layer of concrete

is too thin to work just by itself and the foam is too weak to work by

itself. But when bonded together, the result is something to marvel at

perhaps qualifying as a miracle material.

The Composite, is poised to transform the construction industry by

being stronger, more design-flexible, less expensive and more

sustainable than conventional building materials and methods. It has

the potential to fundamentally change the way construction companies

conceive their projects, now that advanced computer age technologies

have caught up with the imagination of architects and builders to

create better and energy efficient structures. The composite introduces

21st century science, computer technology and mathematics to an

industry that still relies heavily on products and techniques

popularized in the 19th century and used ever since.

GOOGLE has provided a free 3D tool called SketchUp, which could enable

one to design a house online as only you can dream it. With assistance

from our architects your online design idea can become a reality, some

engineering guidelines and restrictions would apply. You could also

select from standard models and easily customize them and drag and drop

features, furniture and appliances etc.

1. Setting up

highly scalable manufacturing and R & D operations ramping up to

thousands

2. Design and

engineering aid

3. Site survey,

recommendations and feasibility process

4. CNC laser

EPS foam cutting operations mobile and base operations (tied into

bill of materials system, work order, MRP system, with bar coding and

RFID)

5. Structural

coating manufacture / mixing operation and storage.

6. Sequencing

Operation and System for delivery of all components to job sites based

on sales order and BOM. This would include the components of the

integrated technologies as well as electrical wiring harnesses and pre

cut plumbing if feasible.

7.

Documentation and certification

8. Online

configuration system with component and feature selection for customers

9. Local job

and skill training programs integrated with active projects.

Other

Integrated Sustainable Technologies

-

LED or

Plasma Lighting

-

Water

Collection & Storage

-

Geothermal

-

Solar

-

Wind

-

Heat

exchange controlled ventilation system

-

Battery

based energy storage

-

IP based

Wireless mesh communications (voice, video, internet data)

-

Anolyte

water purification and sterilization system

-

IP based

Smart House Control System

-

Smart

Electric Grid Interface

-

Epoxy

and Anti-Microbial Coatings

-

Water

and Flood Seal

|

The ultimate in

extreme weather housing, the insulation provided by the composite

materials is effective enough that the house can be heated or cooled

using less than half the energy it takes for a home built with

conventional materials. The foam / concrete house is more resistant to

fire, mold and pests than typical homes, and better able to withstand

such hazards as earthquakes, extreme weather, climate conditions and

flooding with it’s resistance to water. It natural resistance to pests

both insects and rodents reduce the costs associated with pest control,

exposure to toxic pesticides and the diseases transmitted by them. The

available non-porous interior designed without cracks and crevices

makes sterilization and cleaning a breeze. Complimented by the use of a

natural non-toxic residue free biocide, Anolyte solution, the same used

by the human body to destroy pathogens, created using salt water and

sunlight reduces the risk of contagions producing disease.

The ultimate in

extreme weather housing, the insulation provided by the composite

materials is effective enough that the house can be heated or cooled

using less than half the energy it takes for a home built with

conventional materials. The foam / concrete house is more resistant to

fire, mold and pests than typical homes, and better able to withstand

such hazards as earthquakes, extreme weather, climate conditions and

flooding with it’s resistance to water. It natural resistance to pests

both insects and rodents reduce the costs associated with pest control,

exposure to toxic pesticides and the diseases transmitted by them. The

available non-porous interior designed without cracks and crevices

makes sterilization and cleaning a breeze. Complimented by the use of a

natural non-toxic residue free biocide, Anolyte solution, the same used

by the human body to destroy pathogens, created using salt water and

sunlight reduces the risk of contagions producing disease.